Development and delivery of complete electric drive systems

Motors set everything in motion and provide drive power - machines and production lines in industry, equipment and appliances in the office workplace, a wide range of equipment in medical technology and, of course, more and more appliances and furnishings in the home. More and more automation is required for comfort and safety. Everything that turns and moves contains electric drive technology with a DC motor at its heart. This converts electrical power into mechanical power. The simple yet driving functional principle of an electric motor is based on the magnetic effect of electric current.

Electrical drive technology is our expertise

As a competent and experienced system developer and supplier, we integrate and modify electric motors, gears, control units and other assemblies to create drive systems that meet specific requirements. With this wide-ranging, modular product portfolio for electric motors, we can also find customer-specific solutions for almost any application. Our industrial customers in the rehabilitation, medical and measurement technology sectors as well as in machine, plant and equipment construction greatly appreciate this.

What is the best motor choice?

There is no general answer to this question, as it always depends on the application. Frequent load changes, such as with locking systems, versus continuous operation with fans or windshield wipers, or high rotation speeds? In mechatronics studies, a BLDC motor is often recommended because it is more wear-free and has a longer service life than a brushed DC motor. Not wrong in principle, but if the purchasing department looks at the procurement costs, it often comes down to the simple worm geared motor, which, thanks to its sliding friction and self-locking, actually holds what it is supposed to hold in position without additional brakes. But this is not always the case, so let us discuss your application in detail before you decide on a motor type. This can save unnecessary costs.

For decades, DC drive systems and DC motors have proven themselves in daily use and in a wide variety of applications. Their robustness and high reliability make them indispensable in automation technology. They also offer a wide range of economically attractive solutions. Set your criteria for the motor you are looking for in the product filters on the respective product category pages.

Modified motors

Electric drive systems for every application

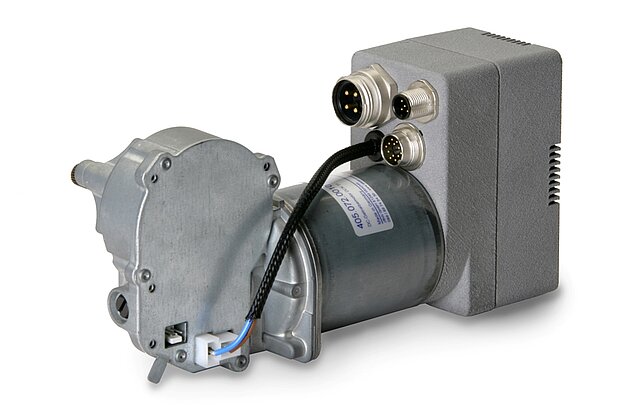

JBW's strength lies in the engineering of individual drive systems, where the motor, gear, encoder, controller, brake, etc. must be optimally matched to each other. For example, we have put together this powerful and reliable geared motor - the intelligent motor for many applications: A worm geared motor with high-resolution encoder and integrated drive and positioning controller. This geared motor offers many advantages:

- Reduced susceptibility to faults, as hardly any wiring is required

- Online monitoring of all motor-relevant states, e.g. rotation direction, current consumption, position

- The digital/analog inputs/outputs both for programs on the controller and via the interfaces can be queried and changed. This means that additional sensors/actuators can be connected directly to the motor.

- Digital inputs programmable for operation via buttons or simple PLC connection

- Central control via CANopen / Profibus-DP interfaces

- Connection via commercially available connectors

Demonstrator for various applications

Let us show you our newly built drive demonstrator with a more complex driving profile and find out what is important for optimally designed drive technology for various applications .