Development phases of a drive prototype

These planetary gear demonstrators can be used to show how an idea for a drive system can be turned into a prototype for a fully functional application across all development phases.

It is important to understand which performance factors come from which components:

- How a planetary gear is constructed with its gradations - seen here from above as well as from the side through the slot.

- How a planetary gear works at different rotation speeds.

- How the driving motor works - the angular gearbox with its bevel gears is shown here.

- What a drive control unit can do.

What needs to be considered when developing a drive system:

- All components - finished and newly constructed - must ultimately fit together in all physical and functional aspects.

- Which components are required.

- Which finished components are available or can be purchased easily and inexpensively.

- Which components can be designed, constructed and manufactured - individual pieces for the prototype in our own workshop or large quantities of e.g. cast parts for series production from a foundry.

- Which additional solutions are required for very specific applications.

JBW develops complete drive systems from a single source for and with its customers for a wide variety of applications.

Do you need a sophisticated drive system for your application?

Planetary gear - manually operated

The planetary gear, which is separated from the motor, can be turned manually via the gear shaft. This makes the way it works obvious: how the planetary gear wheels rotate and how everything interlocks.

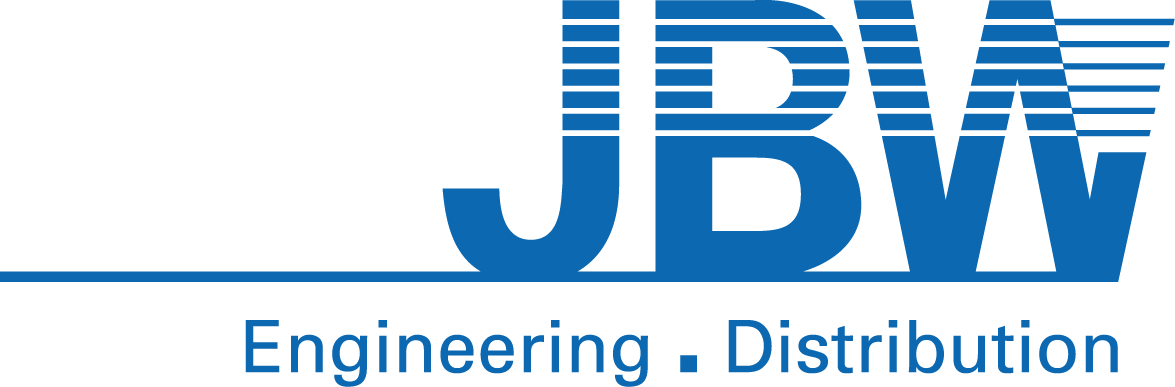

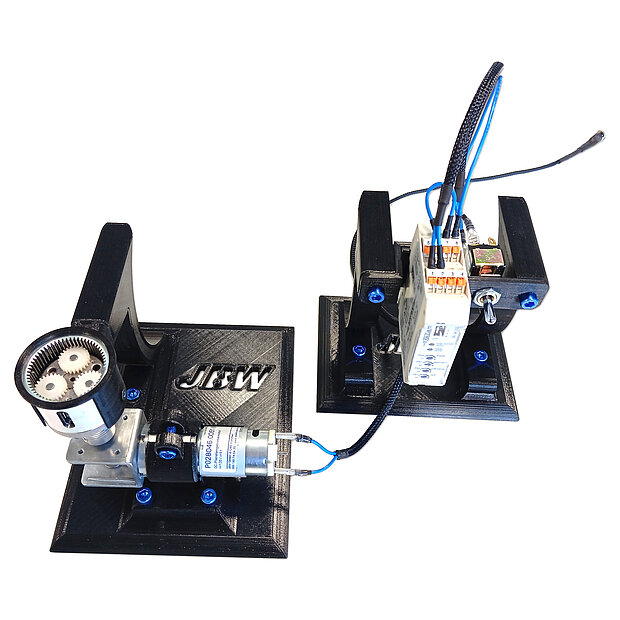

Planetary gear | electronic drive

The structure and function of a planetary gear are demonstrated using a motor and a motor control unit.

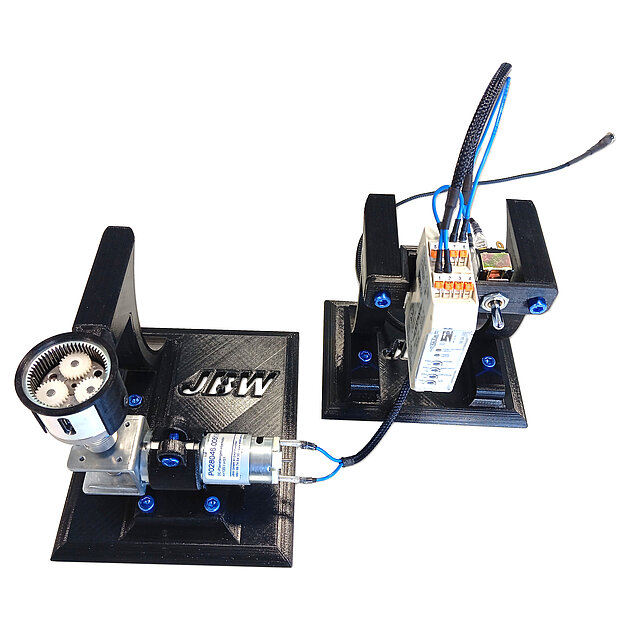

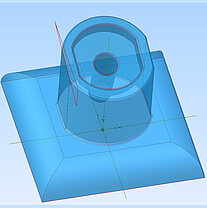

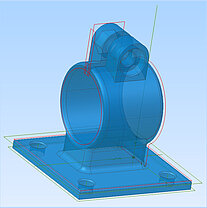

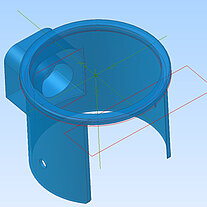

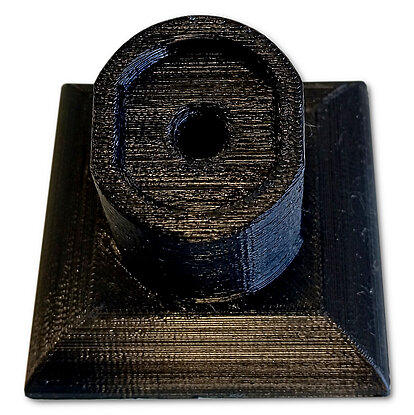

3D printing | Production of components for prototyping

The concept of this demonstrator construction is comparable to prototype construction, in which as many components as possible are to be manufactured in-house. This is why the 3D printer is used for such non-standard components. The individual components are designed and dimensioned in the CAD system in advance. The components for the demonstrator were produced after just a few test prints.

Components used in the electronically controlled drive demonstrator

Planetary gearbox from the P044066 series

The drive demonstrator structure should not be too large. For this reason, a 2-stage planetary gear from the P044066 series is used here. This is visibly installed on the demonstrator.

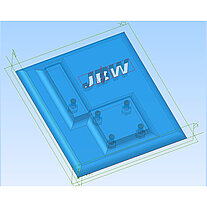

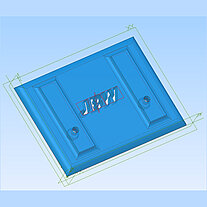

Milled pocket in the gear holder

For an even better insight into planetary gearbox technology, a pocket was milled in a vertical direction along the gear.

The diameter of the milling cutter should not be too large, otherwise the gear wheels in the ring gear would no longer run smoothly.

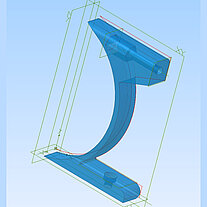

Planetary gear motor with angular gearbox and bevel gears

A planetary gear motor with angular gearbox and bevel gears is used for the electronically controlled demonstrator, motor type P028046.0051.00. The angular gearbox and low torque make it very suitable for this purpose.

Angular gearbox with its bevel gears

The gear cover was removed to reveal the angular gear with its bevel gears.

Shaft clutch

An elastic shaft coupling made of aluminum with grub screws for clamping was selected as the shaft connection. It has two different bore diameters so that the different shafts (D = 8 mm / d = 6 mm) can be connected. This shaft coupling has excellent attributes with regard to loads, which are very desirable for this demonstrator.

Control unit type 06.34.002

The motor controller in this demonstrator is a 24V Kaleja controller type 06.34.002, which is used for brushed motors, as it also has these control options, among others:

- Start/stop ramp

- Short-circuit detection

- Overcurrent shutdown

Toggle switch - changeover contact

A switch is required to switch on and also to reverse the direction of rotation. As two outputs must be assigned for reversing the direction of rotation in the motor control, a changeover contact was selected for this purpose. This toggle switch also matches the design of this drive demonstrator.

Prototype accessories for the eye

Since a prototype not only has to catch the eye, but should also look appealing, the cabling for this demonstrator was made with blue cables and fabric tubing in combination with transparent cable lugs.

Anodized hexagon socket screws

Blue anodized hexagon socket screws were used to connect the individual components. These screws fulfill their purpose - they are corrosion-resistant and lightweight - and also look good. Hexagon pockets were provided in the support elements so that the screws remain in the background, but above all do not have to be countered with tools when tightening. This makes assembly easier.

Components used in the manual planetary gearbox demonstrator

BLDC planetary gear from the P036040 series

A gear from the P036040 series is used for the handy, manually operated planetary gear demonstrator. It clearly shows how a planetary gear works with the running of the three planetary gear wheels.

Planetary gear P036040 - Demonstrator side view

The exposed gear was covered with a 3D printed housing. An acrylic glass pane ensures that the gears remain in position.

3D print holder for the planetary gear

A 3D printed mount with very small tolerances in the clearance fit was produced for the prepared planetary gear. This ensures a good grip during handling.

A wide range of applications - JBW provides creative drive solutions!

As we are increasingly realizing, our customers often no longer have dedicated drive experts with in-depth knowledge of drive technology or where there are no resources available for sophisticated prototyping.

Save your development department effort and money when it comes to a new drive system. Concentrate on your product development and bring in JBW when it comes to the optimum drive technology. JBW engineers think creatively, solution- and cost-oriented. Direct access to a large stock of various BLDC and DC geared motors as well as CAD systems, 3D printing systems and assembly workshops enable to quickly create the perfect drive solution. Your required performance criteria, dimensions of the installation space, etc. are taken into account when developing the prototype. If there are any changes to your product, the prototype can be adapted quickly. We are at your side as a partner in drive systems right through to assembly for series production.

JBW provides you with the optimum combination:

- Electric motors

BLDC and DC motors, gears, control systems - Engineering

Development, design, production / procurement and assembly - Distribution

Warehousing and logistics for punctual delivery to your site.

Meet JBW!

Check our news to see if you can meet us at a trade fair such as SPS in Nuremberg or SPS Italia in Parma in the near future. Bring the specifics of your application with you. We will find the right solution together.

Alternatively, simply give us a call and we can meet online or in person to discuss your application in detail.

Please let us know how such exemplary applications help you and which other applications for electric drive technology you would like to see explained on our website. You can either contact us by phone or email or you can also post your comments on our JBW company profile on Google*).

*) You must be logged into Google to use the link to go directly to the entry field in our company profile on Google. We welcome any kind review, but we also understand anyone who does not want to comment publicly.