Spur Gear Motors

Series Z020032 motor-type Z020032.0018.00

| Motor type | Z020032.0018.00 |

|---|---|

| Type | DC |

| Rated voltage (VDC) | 24 |

| No load speed (Upm) | 403 |

| Rated speed (Upm) | 343 |

| Rated Torque (Nm) | 0.024 |

| Gearbox transmission | 18:1 |

| Gearbox length (mm) | 20 |

| Direction | L/R |

| Shaft 1 | W562 |

| Circuit diagram | S562 |

| Connection | K562 |

Technical description

Crankcase: metal

Magnet field: permanent magnet

Mounting armature: ball or plain bearing

Gear type: spur gear

Gear box: metal

Gear wheel: brass or steal

Lubrication: grease, permanent lubrication

Interface mechanical: output shaft

Interface electrical: cable tin-plated, cable with connector or solder lugs

Notices

Modification of the output shaft with feather or woodruff key, plains or additional internal threat.

Mounting on demand of hall-IC, encoder, tacho sensor or brakes.

If required, we mount and deliver motors with any add-on parts, e.g. rubber-metal buffer, clutch or any brackets.

The right spur gear motor in just three steps

You need the right spur gear motor for your application. Your must-have criteria: Low torques and cost-effective.

We will show you the optimum spur gear motor for your specification. You will receive all motor dimensions and detailed performance data. If necessary, we can also test it on our drive test bench.

S032020 series

Spur gear motor - Fields of application

Automation in industry, office, laboratory and household

Swivel mechanisms; clockworks; tracking systems; positioning systems such as camera movements; office systems such as printers, document shredders, shredders but also computer technology; toys; ticket machines; contact closers; laboratory systems; kitchen appliances; dosing systems etc.

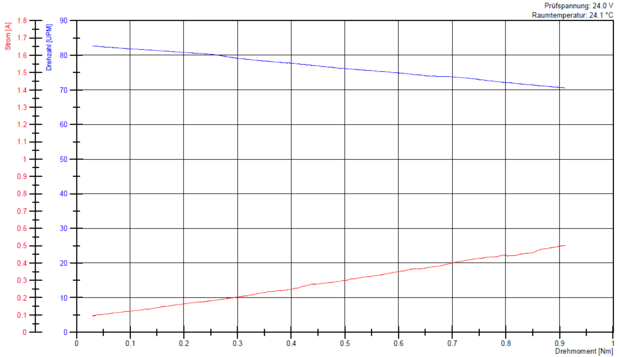

Motor characteristic curve

We also provide you with the characteristic curve for each motor, as we test it as standard under load on our own drive test bench. If you want to know specific load values for your application, we will be happy to adjust them on request.

Spur gear motor | Your questions & answers

Yes, the rotation speed of spur gear motors can be controlled with a PWM signal.

Yes, a spur gear motor can reach +60 degrees Celsius during operation, depending on the model.

Yes, if the supply voltage is throttled, the rotation speed drops.

Please send us an e-mail to info@elektromotore.eu with your contact details and the engine for which you require the CAD model.