Drive technology | Development and delivery of complete drive systems

JBW GmbH is a reliable development partner and supplier in the field of electrical drive technology for its industrial customers and dealers at home and abroad. High-quality DC and BLDC motors, a wide range of gears, controllers, toroidal transformers and associated mechatronic components are part of our assemblies and reflect our core competence in engineering. Finding interesting solutions for demanding industrial applications is something that our customers in the rehabilitation, medical and measurement technology sectors as well as in mechanical, plant and equipment engineering appreciate. All drive components are procured in a customer-oriented manner and delivered on time via an in-house warehouse. Our customers benefit from short response times, high delivery availability and flexibility. These combined strengths are crucial for industrial manufacturers.

Meet JBW at the industrial trade fair SPS 2025!

In Nuremberg from 25. to 27. November 2025

You can find JBW at booth 218 in hall 1. We have our latest BLDC and DC motors with us!

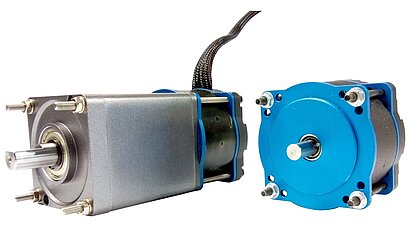

Two new planetary gear motors

Product announcement | P016024 and P016025 series

New BLDC planetary gear motors from the P016024 series

Spindle motors - high-precision with the best results- New DC planetary gear motors from the P016025 series

With hexagon socket shaft for special smart home applications

New BLDC planetary gear motors

Product announcement P042066 series

A planetary gear motor combines a compact design with high efficiency. This new BLDC motor with planetary gear from the P042066 series promises not only rated power but also a long service life. This BLDC planetary gear motor is available in two variants. Both have a gear with two ball-bearings and reinforced planetary gears, which ensure high torque and low gear backlash. In the second variant, the first stage of the planetary gear has helical teeth and is made of plastic , which significantly reduces running noise.

The right DC or BLDC geared motor in just three steps

You need the right DC or BLDC gear motor for your application.

We suggest the optimum geared motor based on your specifications. In addition to detailed diagrams and characteristic curves, we also supply load case results from the drive test bench.

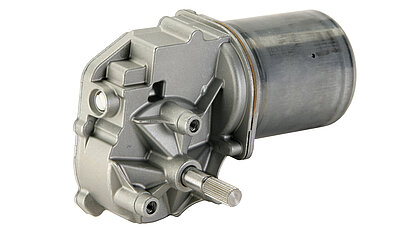

Worm gear motors

DC motors with worm gearboxes are always a good choice in case of doubt, as they are robust and inexpensive. A worm geared motor is ideal when the application requires high torques and low rotation speeds. It runs quietly even under high loads.

Spur gear motors

DC motors with spur gears are ideal for all drive systems with parallel outputs (central or decentralized gear shaft output), as well as for higher torques and lower rotation speeds. These are also decisive criteria: A spur gear motor is powerful and yet space-saving, which can be a decisive factor in small installation spaces, e.g. for office equipment and laboratory equipment.

Planetary gear motors

DC motors with planetary gears are ideal for all applications that require low output speeds and high torque at the same time. A planetary gear motor is compact in all series and yet so powerful thanks to the high transmission ratios and the wide range of drive transmissions. As an option, we can also add hall-IC and other components to the desired planetary geared motor so that you get the best technical solution for many industrial, household or building equipment applications.

BLDC motor

A brushless DC motor ( BLDC motor for short) is powerful and particularly durable because its mechanical structure works without brushes and other wear parts. The compact case, which fits into almost any small installation space, has a higher power density compared to a brushed DC motor. It is also energy-saving. For these reasons, BLDC motors are often used in medical technology and robotic systems.

High-torque BLDC motor

The new technology of this high-torque BLDC motor opens up new dimensions in drive technology: in combination with the case-relevant gears, this motor with its small dimensions and weight achieves a very high level of efficiency. It runs extremely smoothly, smoothly and quietly and guarantees a long service life. This patented motor technology combines the advantages of classic DC motors with fully electronic commutation. The integrated electronic control with encoder covers a wide range of applications. The finely adjusted rotors are powerful, precise and cogging-free for systems and devices in laser technology and medical technology.

Motors without gear

We offer DC motors without gear in several variants. You can use our product filter to easily narrow down the right DC motor for your application where you already have your own gears. Or where you have permanently installed gears to minimize gear backlash in the application, but where you still need high rotation speeds.

Motor controls

Our electronic control units for DC motors and BLDC motors - both in standard and customized versions - are equally suited to a wide range of requirements. They are compact and robust and can be connected via standard plug contacts. Each controller is programmable and uses digital and analog inputs and outputs to control everything from rotation direction and speed to ramps, dynamic braking and power supply, etc.

Toroidal transformers

We produce our own low-noise toroidal transformers in common standard designs especially for applications in control technology and in plant and appliance construction. They promise high efficiency, low power loss and optimum temperature behavior. On request, we can also supply special variants in other sizes, rated powers or with additional magnetic or electrostatic shielding. And the following always applies: every toroidal transformer is manufactured and tested in accordance with the applicable guidelines for safety transformers.

Drive adaptation

Mechatronic automation would be unthinkable without precisely matched drive technology. Convenience, reliability and safety are immediately invalidated as soon as the drive system does not meet the respective technical requirements. So there are always two sides to the adaptations - adaptation of the drive technology or the application.

Mobile measurements

Our industrial customers call us for help when their customers report unexpected problems with series devices in which they install our electric motors. We diagnose the cause of the problem and often quickly identify the only correct solution. Our expertise is also in demand when it comes to deciding on the right electric drive technology during prototyping. Our measurements provide clear, irrefutable facts.

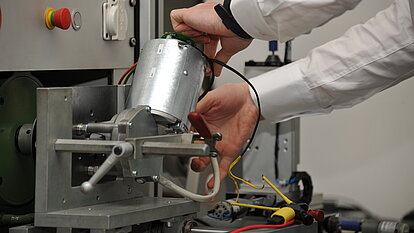

Drive test bench

Our service for the right selection and equipment of drive technology: To evaluate the load capacity and functionality of electric motors, we record the performance facts with the characteristic curves for current, voltage, rotation speed, torque and temperature, among other things, on our motor test benches, some of which we have developed ourselves. Together with the measurement data of the application-specific load characteristics, which are obtained with a digital storage oscilloscope on the prototype, the optimum for a drive system is determined. This provides valuable information and confirmation before the final motor is selected and released for series production.

Kinematics concepts

As is so often the case, the key lies in the design and sequence, which is why we are happy to support you in the development of application-specific kinematics concepts, as this allows the desired rated power to be optimally correlated with the drive technology used. Whether it is a television in the luxury segment, a bathtub lift or a production machine - we test on site at the customer's premises for a snapshot with a mobile measurement or with endurance tests in our own facilities to determine whether and to what extent the pre-selected drive technology components harmonize with the requirements of the respective application. This provides valuable findings for prototypes as well as series devices. We document in detail which forces are at work and when, for example, an unintentional premature shutdown occurs. Our engineers consider how motion sequences and the drive technology used can be optimally coordinated.

Assembly of drive systems

We are happy to take on the assembly of complete drive systems, from small series to large series. We professionally assemble all specified components for our partners and industrial customers in our own workshops: DC motors with drive shafts, control units, power supply units and associated installation parts such as metal brackets etc. We benefit from the many years of cooperation between our development engineers and assembly personnel, as this enables us to work hand in hand from prototyping to series production and quickly identify the smallest deviations in the assembly processes. We also meticulously implement our high quality standards here, i.e. external assembly personnel are first carefully instructed step by step.

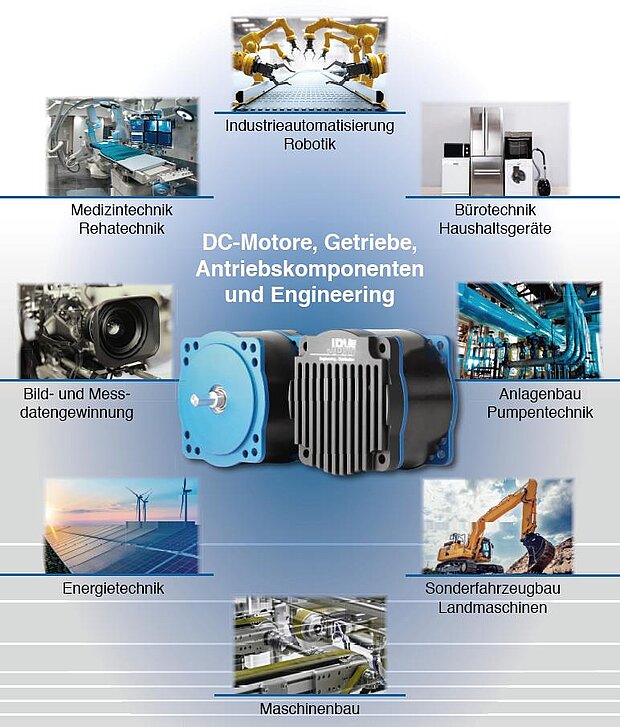

Fields of application | Automation in industry and household

Industrial automation and robotics

Office technology and household appliances

Plant engineering and pump technology

Special vehicle construction and agricultural machinery

Mechanical engineering

Energy technology

Image and measurement data acquisition

Medical technology and rehabilitation technology

Recognized benefits for drive technology from JBW

Engineering and distribution from a single source

Broad product portfolio of DC geared motors

All components for complete drive systems

Drive module - tested and logged

Engineering support - development, testing, optimization

High delivery capability thanks to large stock

Owner and Managing Director JBW GmbH

Long-standing customer-supplier relationships provide stability

"Both our industrial customers and we appreciate the constructive cooperation at eye level. Nowadays, drive technology solutions require a skillful combination of high-quality electric motors, optimal gears, intelligent control systems and a wide range of variations for all associated components. In addition, the best technical solutions also require reliable delivery capability. You can get all of this from a single source - from JBW GmbH in Munich."

I look forward to your call

Tel. +49 89 89745430

Electric motors and drive systems | Your questions & answers

It always depends on the application. A brushless motor with fewer wearing parts has its advantages just as much as a robust worm geared motor. But there are various ways to achieve a long service life, for example by designing the lubrication of the geared motors according to the application.

We have the corresponding CAD data as well as motor characteristics, circuit and connection data for all electric motors. Please send us an e-mail to info@elektromotore.eu with your contact details and the motor for which you require the CAD model.