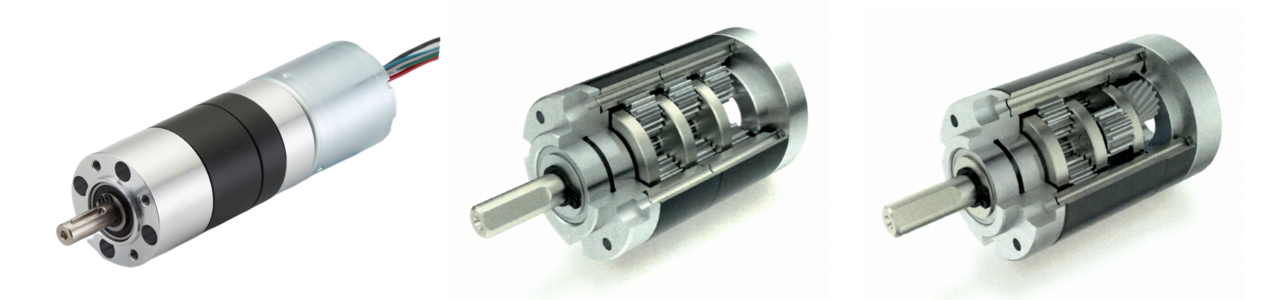

A planetary gear motor combines a compact design with high efficiency. This new BLDC motor with planetary gear from the P042066 series promises a long service life in addition to its rated power. This BLDC planetary gear motor is available in two variants. Both have a gear with two ball-bearings and reinforced planetary gears, which ensure high torque and low gear backlash. In the second variant, the first stage of the planetary gear has helical teeth and is made of plastic, which significantly reduces running noise.

The P042066 series can be used in applications that require high radial forces in addition to high torques, such as pulleys mounted directly on the motor shaft - the mounting of the motor shaft must reliably withstand the voltage of the belt over its entire service life. In addition, these BLDC planetary gear motors are used in high-precision applications where low gear backlash is required, e.g. for the positioning drive of laser optics, in mechanical processing centers or order picking systems.

A planetary gear has a special design: several planetary gears rotate around the central sun gear and simultaneously around the outer hollow gear. This design results in a high reduction ratio, which in turn leads to a high torque output from the motor. Another advantage of a planetary gear motor is its high efficiency. As the teeth of the gears never lose contact, there is only a small loss of energy due to slip or friction. This allows the motor to work more efficiently than with other gearbox types.

We can also customize these BLDC planetary gear motors with additional components such as Hall-ICs, encoders, special shafts and brakes to optimally support your application.