Spur Gear Motors

Series S070045 motor-type S070045.0080.03

| Motor type | S070045.0080.03 |

|---|---|

| Type | BLDC |

| Rated voltage (VDC) | 24 |

| No load speed (Upm) | 31 |

| Rated speed (Upm) | 26 |

| Rated Torque (Nm) | 20 |

| Hall sensor | 816 pulses / integrated |

| Gearbox transmission | 80:1 |

| Shaft 1 | W984 |

| Connection | K584 |

Technical description

High-Torque BLDC geared motor

The new drive technology of this high-torque BLDC motor makes it true: Very high efficiency by small dimensions and weight, an extremely steady, smooth and quiet running as well as a long lifetime.

This brushless motor operates on a patented axial flow double disc rotor principle with continuous commutation. The fully integrated electronics, which is matched to the motor characteristics, takes over the motion control. The geared motor achieves the exceptionally high torque density with high overload capacity and adjustment dynamics. A specially developed air anchor principle is used instead of the usual slot anchor. This ensures perfect cogging torque, excellent running smoothness and fast and accurate fine positioning. Typical application areas where this high accuracy and reliability are important:

- Industrial Automation and Robotics

- Medical technology

- Measuring and imaging system technology

In addition to the electronic commutator, which is controlled by a programmable logic (CPLD), a microcontroller is integrated in the motor, which in the normal version controls direction, PWM speed with ramp functions for acceleration and deceleration as well as various protection functions and fault analyzes. An incremental encoder with pulse counter is also included, which can be used to control speed as well as the position in multi-turn mode. By modifying the firmware, it would be possible despite the large gear reduction to control an oscillating motion, as used in the windshield wiper drive, even over many motor rotations (transmission input). Thus, a single additional position sensor on the output - meaningful with switching point in the middle of movement - would suffice to detect the absolute position during switch-on (or during basic initialization) and then to perform a sine-like motion control in the reversal points. In addition to this smart motion, the wear of all moving parts and current peaks are reduced. In this case, the additional position generator can be directly connected with an input line of the integrated motor electronics, so that besides to a start-stop line no further external controls are needed. We will gladly check further special function on request.

Crankcase: metal

Magnet field: permanent magnet

Mounting armature: ball bearing

Gear type: spur gear

Gear box: metal / plastic

Gear wheel: steel

Lubrication: grease, permanent lubrication

Interface mechanical: output shaft, also possible on both sides

Interface electrical: cable tin-plated or cable with connector

Notices

Modification of the output shaft with feather or woodruff key, plains or additional internal threat.

Mounting on demand of hall-IC, encoder, tacho sensor or brakes.

If required, we mount and deliver motors with any add-on parts, e.g. rubber-metal buffer, clutch or any brackets.

The right spur gear motor in just three steps

You need the right spur gear motor for your application. Your must-have criteria: Low torques and cost-effective.

We will show you the optimum spur gear motor for your specification. You will receive all motor dimensions and detailed performance data. If necessary, we can also test it on our drive test bench.

S032020 series

Spur gear motor - Fields of application

Automation in industry, office, laboratory and household

Swivel mechanisms; clockworks; tracking systems; positioning systems such as camera movements; office systems such as printers, document shredders, shredders but also computer technology; toys; ticket machines; contact closers; laboratory systems; kitchen appliances; dosing systems etc.

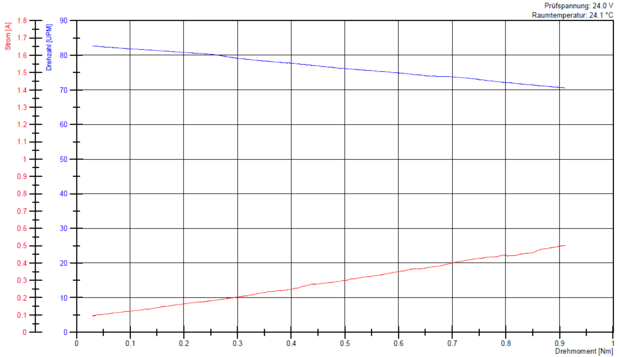

Motor characteristic curve

We also provide you with the characteristic curve for each motor, as we test it as standard under load on our own drive test bench. If you want to know specific load values for your application, we will be happy to adjust them on request.

Spur gear motor | Your questions & answers

Yes, the rotation speed of spur gear motors can be controlled with a PWM signal.

Yes, a spur gear motor can reach +60 degrees Celsius during operation, depending on the model.

Yes, if the supply voltage is throttled, the rotation speed drops.

Please send us an e-mail to info@elektromotore.eu with your contact details and the engine for which you require the CAD model.