Product Filter

No match for the required drive component here?

Oh, then we have not yet included the right product for your requirement criteria in our online product database

But maybe in our warehouse after all!

We have almost countless types of DC motors and drive components on offer and many are even available in stock. Or we can assemble the complete drive system specifically for your application. We would be happy to work with you to consider which configuration might provide the optimal drive. Just talk to us directly!

New in the product catalog | BLDC motor with new planetary gear

In the new P042066 series, a BLDC motor is equipped with a new planetary gear in two variants. Both variants have double ball bearings and reinforced planetary gears.

Technical data of the LN planetary gear

- Voltage: 24 VDC

- Rotation speed: 11 to 800 rpm

- Torque: 0.5 to 13.2 Nm

- Gear with two ball-bearings and reinforced planetary gears

- A variant with helical-toothed plastic gears in the first stage

Advantages of this LN planetary gear

- High torques

- high efficiency

- Low gear backlash

- Low noise in the variant with plastic gears

Areas of application

- In high-precision applications that require low gear back lash, e.g. in the positioning of laser optics, in mechanical processing devices or in order picking systems.

- The variant with plastic planetary gears is mainly used in noise-sensitive applications.

Why does a manufacturer need this LN planetary gear?

- LN planetary gears are technically far superior to conventional planetary gears in all areas. Especially when it is controlled electronically, as the data can be utilized much more precisely.

- An LN planetary gearbox largely eliminates the weaknesses of a conventional planetary gearbox.

Differences between the LN planetary gear and conventional planetary gears

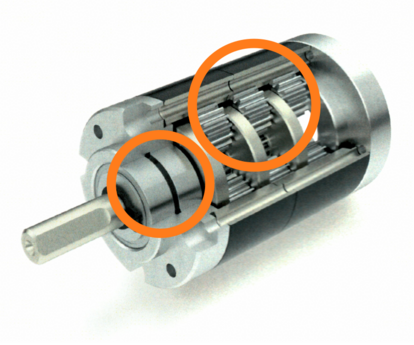

Double ball bearing

- Withstands radial forces better, e.g. mounted belt pulley.

- Protects the planetary gears from overload

- Significantly longer service life

- Higher power transmission possible

Reinforced planetary gears

- Improved force distribution due to wider contact surfaces

Plastic gears in the first stage

- Helical-toothed planetary gears

- Engage in stages

- Smooth transition of forces

- Reduced vibrations and shock loads

- Less noise

- Less wear

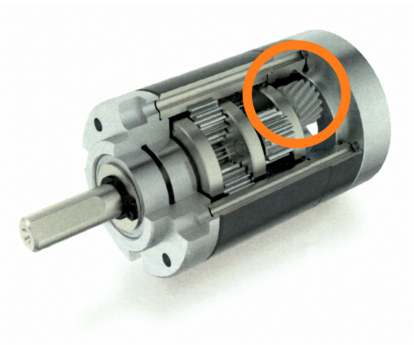

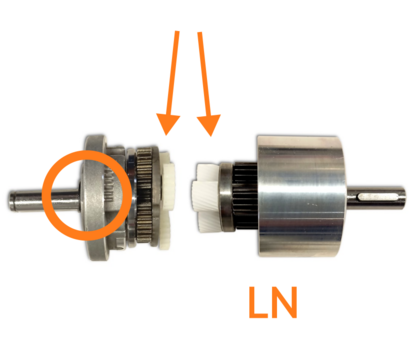

Comparison

- On the left, a conventional planetary gear with one ball-bearing and narrower planetary gears

- Right the LN planetary gear with double ball-bearings and reinforced planetary gears (here variant with helical-toothed plastic gears)

Two further announcements of new planetary gear motors

BLDC planetary gear motor of the P016024 series

Precise drive due to optimum concentricity of the spindle

Spindle motors - indispensable in modern technology

- Spindle motors work with high precision with the best results in terms of quality, productivity, process reliability, workpiece accuracy and surface quality

- The spindle bearings ensure that the spindle runs almost free of play and can withstand high radial and axial loads.

- The low inertia of the spindle enables high rotation speeds as well as optimum acceleration.

- Spindle motors contain all the necessary components in a compact form.

Advantages

- Compact and space-saving design

- High efficiency

- High operating process reliability

- High static and dynamic rigidity

- High concentricity

- Low friction losses

- Low wear

- Low maintenance requirements

Applications

Spindle motors are used in almost all branches of industry.

DC planetary gear motors of the P016025 series

For special applications with special shaft

Planetary gear motors with hexagon socket shaft for simple, fast and cost-effective adaptation

- Torque transmission through special flange

- Optimum power transmission thanks to positive shaft-hub connection, without using of grub screws or similar connecting elements

- No material weakening due to split pin connection etc.

- Easy to insert and replace thanks to the motor geometry

Advantages

- Very quiet running noise, therefore perfect for everyday domestic life environment

- Precise, compact, efficient and energy-saving operation thanks to low power consumption

- Low space requirement due to compact design

- Simple maintenance

Applications | Smart home automation

- Roller blinds, awnings, Venetian blinds

- Lighting

- Heating

- Camera

Our best planetary gear motor for you in just three steps

You need a DC geared motor for your application where the installation space only permits inline installation. Your other must-have criteria: Strong forces and strong output force.

We will show you the optimum planetary gear motor for your specification. You will receive all motor dimensions and motor diagrams as well as the desired characteristic curves. If necessary, we can also test the motor extensively on our drive test bench.

Fields of application for planetary gear motors

Automation in industry and the home

Flap drive, valve drive, automatic closing aid or opening aid for doors, locking system, motorized tool, positioning system, actuator, lifting system, line drive, display adjustment, model making, mills; drying processes in the building materials industry, filling processes in the cement industry, slow-running process engineering systems, e.g. mixers, rotary filters, also in the food industry

Series can be modified and extended to meet requirements

Here you will find your desired planetary gear motor in various series to help you make the right choice. The grouping into series indicates the respective case and identical gearbox parts. The other equipment can be optionally configured to suit the specific application.

- Modification of the output shaft with keyway or woodruff key, flats or additional internal threat

- Attachment of Hall-IC, encoder, tacho or brakes

- Assembly with attachments specified by you, e.g. rubber-metal buffer, clutch or angle bracket

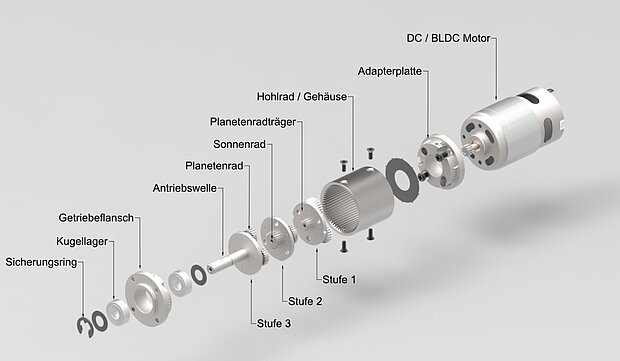

The exploded view shows the complex design of a planetary gear motor with a three-stage gear. Each gear stage reduces the rotation speed and increases the torque. The high torque is distributed over several gear wheels. The gears in the first stage are usually made of plastic to reduce noise. The first stage rotates very quickly - most DC motors at 5000-9000 rpm. The other gears are made of plastic or steel. If a different gear ratio is required, we can easily equip the DC motor with a different gear to suit your application.

A planetary gear motor can be louder than a DC motor with a different type of gearbox. Any noise that occurs can be additionally insulated by installing helical gears. We know how different noise emissions are from cars, for example: forward gears are usually helical and quiet, while reverse gears are usually straight and make a characteristic whining noise.

Unfortunately, it is often neglected that simply using a long-life grease helps a planetary gear motor to be very reliable and durable.

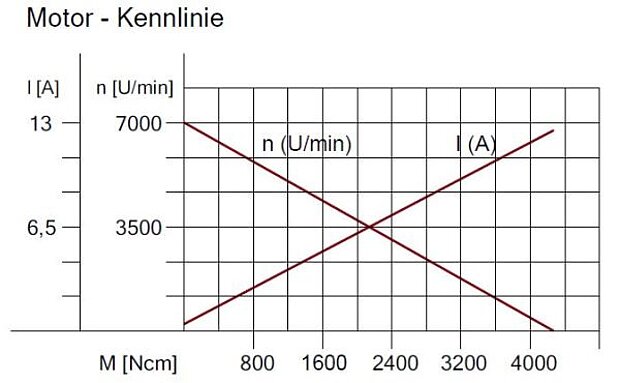

CAD data and motor characteristics

If you also require CAD data, we can provide it on request. We have CAD data and motor characteristics for each of our planetary gear motors. The latter show you the rotation speeds at which the corresponding torques are achieved. The current consumption is also shown.

Planetary gear motor | Your questions & answers

A motor characteristic curve is a diagram that shows the behavior of a planetary gear motor based on current consumption, rotation speed and torque.

Yes, almost all of our control systems are PLC-compatible.

A Hall-IC is a sensor that detects magnetic fields. It is often used in conjunction with a planetary gear motor to determine rotation speed and rotation direction.

Interesting facts from the press

How does the planetary gear of an automatic gearshift in a vehicle work?

Planetary gears, also known as planetary gears, are machine components that are blessed with some very advantageous attributes and therefore shine in all kinds of applications. They function as distributor or summation gears, as very compact transmission stages and as the core of classic automatic transmissions.

Read more How does the planetary gear work?